|

|

| ART OF WELDING

The high quality and aesthetics are illustrated

in these pictures... All welds show the masterful design of the engineer

and the artistic execution by the welding specialist.

|

|

| Attention is paid to every detail. Even

the welding of the stabilizing pipes of the fermenters is a piece of art...

We at Bavarian consider one single most important goal: QUALITY. |

|

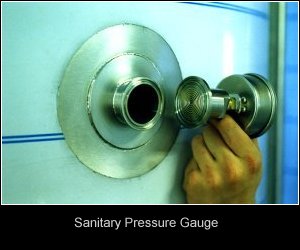

MINIMIZING POTENTIALS FOR BACTERIA

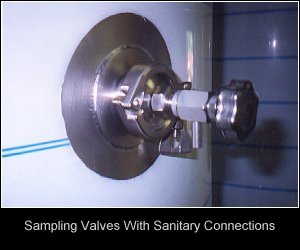

WHILE MAXIMIZING C.I.P. EFFICIENCY To avoid creating a hotbed for bacteria, there are no threaded fittings on Bavarian’s fermenters, bright beer tanks, serving tanks. The use of sanitary connection also allows for easy cleaning and handling. Pressure Gauges Our standard pressure gauges are made of stainless steel. They are attached to a diapragm shell which passes the pressure to the gauge’s bi-metal sensor. The diaphragm is laser-welded to the fitting to avoid direct contact with the gauge. Sampling valves The sampling valve

is attached to the tank through a sanitary clamp adapter that is welded

(sanitary) to the neck of the valve. The valve is easily cleanable either

in CIP process or detached.

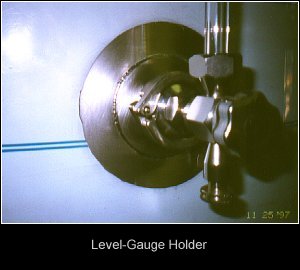

Level-gauge Similar to the sampling

valve, both the upper and the lower fitting of the level-gauge holder are

attached to the tank by a clamp.

Thermo-wells A 6” clamped stainless steel thermowell is used to avoid direct contact of a thermometer or sensor with the beer. Easily cleanable and detachable. |

| Bavarian Brewery Technologies - Tel.: (310) 391-1091 - Fax: (310) 391-4530 - email: brew@idt.net |